History of Precise Metal Production – Precision metal parts

Precise Metal Production GmbH & Co KG was originally founded on 1 January 1986 by Hubert Gissler in Zell-Unterharmersbach in rented premises.

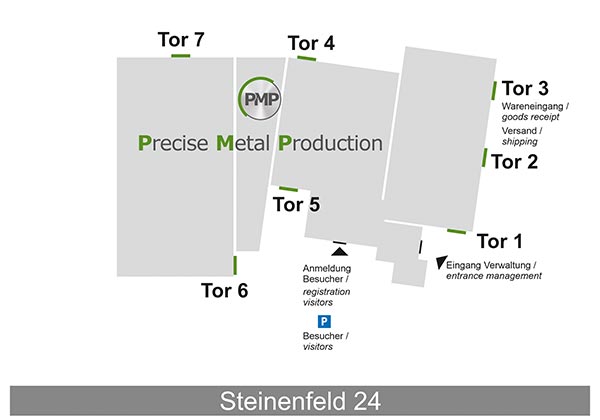

Soon the premises were too small, so that the construction of an own production hall with office wing (altogether 900 sqm) in the industrial area Steinenfeld in Zell am Harmersbach was necessary. In the following years the production area was extended by a second hall with 580 sqm.

The level of awareness as a specialist in metalworking for CNC turning, milling and grinding rose continuously both nationally and internationally.

Therefore, in November 2011, the new construction of a third production hall with an office wing for the areas of work preparation, quality assurance and production management was completed with a total of 1,290 sqm. The office wing also includes a fully air-conditioned measuring room with a vibration-free floor. At the same time, the two lathes MORI SEIKI NL2500SY/ 700 and MAZAK QT Smart 350 were added to the machine park.

Atthe beginning of 2014, the company entered the field of gear hobbing with the corresponding production and measurement technology: External / involute gearing (hobbing, up to module 6) as well as spur / hirth gearing.

Atthe end of 2014 and beginning of 2015, the machine park was expanded by a highly efficient multi-axis turning center MORI SEIKI NZX 2000/ 800SY and MORI SEIKI NZ2000 T2Y, each with two turrets and Y-axis, for high-precision machining of complex workpieces at maximum productivity.

Effective October 1, 2015, three operational managers became shareholders in the company in addition to Hubert Gissler: Managing Director Christian Wordl (34%), Production Manager Karl-Heinz Spitzer (8.5%) and QA Manager Armin Leopold (8.5%). The additional capital contributions were used exclusively to increase the company’s capital.

Atthe beginning of 2016, the company expanded to include a high-precision MORI SEIKI NLX2500SY/ 700 lathe with a turret and Y-axis.

Inmid-2016, the company entered the field of laser marking with the GRAVOTECH TF420 fiber laser station and subsequently expanded its machinery with two high-precision MORI SEIKI NL2500SY/ 700 lathes with a turret and Y-axis.

At the end of 2017, the machine park was expanded with a new high-precision MORI SEIKI NLX2500SY/ 700 lathe with a turret and Y-axis as well as a robot interface.

At theend of 2018 and beginning of 2019, a new high-precision lathe MORI SEIKI NLX2500SY/ 700 with a turret and Y-axis and a MORI SEIKI NL2000/ 500 were added again.

On January 2, 2020, the managing partner Christian Wordl additionally took over the company shares of the previous main shareholder Hubert Gissler amounting to 49% in full and thus now holds 83% of the company. The remaining 17% continues to be divided equally between the operating shareholders Armin Leopold as Quality Manager and Karl-Heinz Spitzer as Purchasing Manager.

Hubert Gissler, who has no longer been operationally active in the company since mid-2013, remains the lessor of the premises with the three production halls including office building, for which a total 20-year lease agreement exists.

In May 2020, the machine park was expanded to include a Kellenberger cylindrical grinding machine KEL-VISTA UR 175-1000, which is as good as new, and the measuring room was expanded to include a form and position measuring device MITUTOYO Roundtest RA2200AH.

Effective June 18, 2020, our QA Manager and Human Resources Manager Armin Leopold has additionally taken over Karl-Heinz Spitzer’s company shares in full and thus holds 17% of the company shares.

In August 2020, a new EMAG VL 4 turning centre with FANUC control and integrated pick-up automation was added to the machine park; the VL 4 is a vertical turning machine for the productive production of chucked parts up to 200 mm in diameter.

In September 2020, a new multifunctional Tool Management System from GÜHRING for tools and measuring equipment was installed.

In mid-November 2020, a new MORI SEIKI NLX1500SY/ 500 high-speed lathe with a turret and Y-axis for smaller internal and external diameters and a new MORI SEIKI NTX1000SZM high-precision milling/turning center with a 76-station tool magazine and 12-station turret were added.

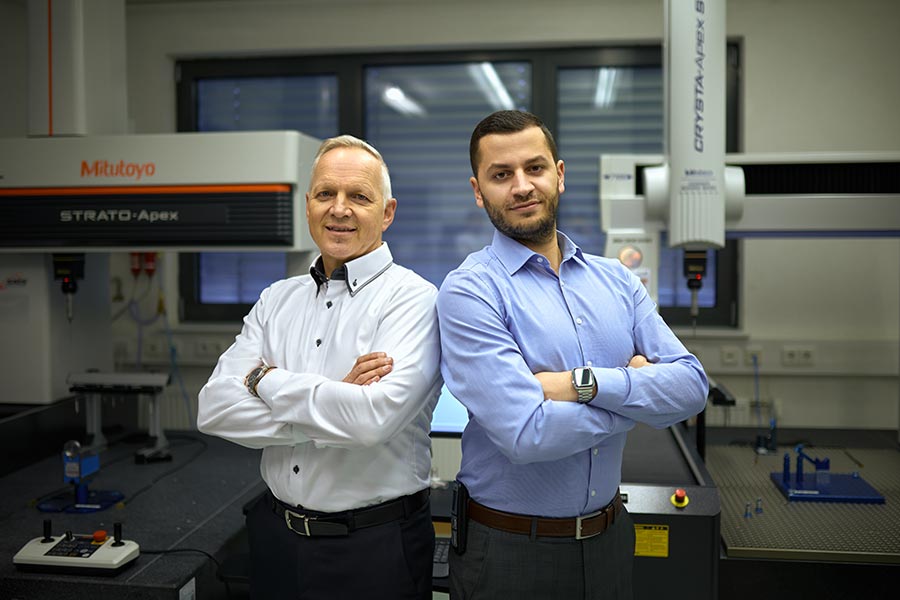

From January 2021, our company will operate under the legally effective name Precise Metal Production GmbH & Co. KG (instead of GISSLERprecision GmbH & Co. KG). This also involved a change in the shareholder structure, although three operational managers remain shareholders in the company: Managing Partner Christian Wordl (58%), Production Manager Benjamin Hermann (30%) and QA Manager/Human Resources Manager Armin Leopold (12%). The additional capital contributions were used exclusively to increase the company’s capital.

In March 2021, a high-precision MORI SEIKI NLX2500SY/ 700 lathe with a turret and Y-axis was added to the machine park.

In October 2021, a highly efficient MORI SEIKI NZX 2000/ 800SY multi-axis turning center with two turrets and a Y-axis was added.

In January 2023, the machine park was expanded to include a new high-precision MORI SEIKI NLX2500SY/ 700 lathe with a 20-position turret and Y-axis as well as a 100 mm bar capacity with more powerful drive motors on the main and counter spindles, direct path measuring system on all 3 axes and robot interface.

In July 2023, the machine park was expanded with another new high-precision lathe MORI SEIKI NLX2500SY/ 700 with a 20-position turret and Y-axis as well as a 100 bar capacity with more powerful drive motors on the main and counter spindles, direct path measuring system on all 3 axes and robot interface. At the same time, this machine was supplemented by a GILDEMEISTER Robo2Go flexible workpiece loading and unloading system. The robot control is fully integrated into the machine’s app-based CELOS® control system. This is the first plug & produce automation with a robot at PMP. Furthermore, the robot can be used flexibly on several machines.

With effect from August 01, 2023, our production manager and authorized signatory Benjamin Hermann has additionally taken over Armin Leopold’s company shares in full and thus holds 42% of the company shares. In the course of this, he also became a managing partner alongside Christian Wordl (58% of the shares).

The new detailed planning tool etagis APS Professional was introduced at the beginning of August 2023 . With etagis APS Professional, production order processing is optimized by detailed planning against limited capacity. The manufacturing processes are mapped realistically and the enormous amounts of data, dependencies and restrictions in manufacturing are thus manageable. Production capacity utilization is thus monitored and material and capacity bottlenecks are detected at an early stage. It enables transparent and forward-looking planning as well as graphical simulation of different scenarios and optimization of resources. PMP’s customers receive even more reliable statements on completion dates and delivery capability through interactive production planning and control.

In September 2023, another GILDEMEISTER Robo2Go flexible workpiece loading and unloading system was added. The corresponding robot control is fully integrated into the machine’s app-based CELOS® control system. This is the second Plug & Produce automation with a robot at PMP. The robot can also be used flexibly on other machines.

At the end of October 2023, a new high-precision MORI SEIKI NLX2000/ 500 lathe with a 20-position turret and DMG MORI GX-05 gantry loader automation system was added to the machine park. This is the first gantry loader system with highly productive and flexible workpiece handling in production at PMP. Programming and set-up is carried out by integration via the CELOS® machine control system and loader status monitoring is also carried out via the DMG MORI Messenger.

At the end of November 2023, a new high-precision Mitutoyo STRATO-Apex 7106 3D coordinate measuring machine with an accuracy class of 0.7 µm was put into operation. In the fully air-conditioned measuring room, this complements the existing Mitutoyo CRYSTA-Apex S 7106 with an accuracy class of 1.7 µm as well as the contour measuring station and the high-precision Mitutoyo Roundtest RA-2200AH form/position measuring device with an accuracy class of 0.5 µm. The high-precision CNC 3 coordinate measuring machine enables highly accurate measurement results to be achieved at high speeds. PMP thus not only consistently expands the possibilities for even more precise metal processing, but also massively increases production throughput.

The 3rd Robo2Go loading and unloading robot was put into operation in December 2023. The multifunctional robot from DMG MORI AUTOMATION is stationed on a MORI SEIKI NZX2000/ 800SY. Robot operation is integrated into the machine’s app-based CELOS® control system. This robot can also be used flexibly on another CNC machine with CELOS® control; 9 corresponding MORI SEIKI machines are currently in use.

In February 2024, three STUDER cylindrical grinding machines were installed in the grinding area: S33_1045 CNC, S30-1 and S-20 Favorit. Another new CNC universal cylindrical grinding machine S33_1045 with rotating dressing spindle, pneumatic power chuck, synchronous tailstock and app-based C.O.R.E. control as well as active cooler for cooling lubricant and spindle has been ordered and will be delivered in April 2024.

In June 2024, a new highly productive GILDEMEISTER SPRINT 42 linear CNC automatic lathe with 8 axes, linear drive and 26 tool stations was put into operation in conjunction with a 3.2 m IEMCA Boss 552/32 bar loader. The machine’s thermo-symmetrical design and integrated position measuring system ensure maximum precision, while the special ball guides guarantee constant rigidity. A FANUC 310i panel with SLIMline control panel and 15″ monitor as well as sister tool management and tool wear monitoring with Tool Monitor is used as the control system.

With these continuous investments, the company remains technically up to date and sets the course for further challenges in the field of demanding precision metal parts.

Share page: